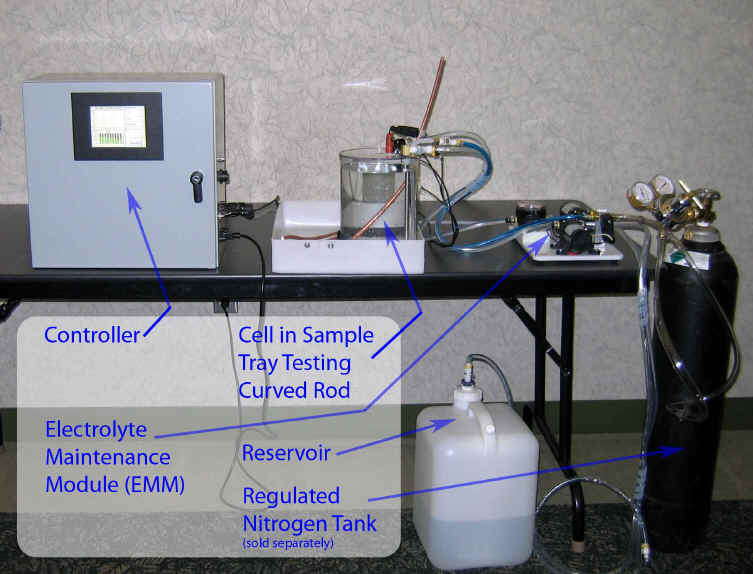

(1) Controller

(1) Electrochemical Cell

(1) Tray for Holding the Cell and Samples

(1) Electrolyte Maintenance Module (EMM)

(1) Electrolyte Reservoir

(1) CD containing the following files:

Digital Manual

Upload Manager Software

Test Capture Software (for advanced use only)

(1) Hardcopy of Manual Chapters 1 through 4 (25 pages)

(1) Coil of Copper Foil

(1) Power Cord

Stainless Steel Stand

Second Reservoir for Used Electrolyte

Rapid Insertion Foil Holder for Physical Calibration

Wire Holder for Testing Wires

![]()

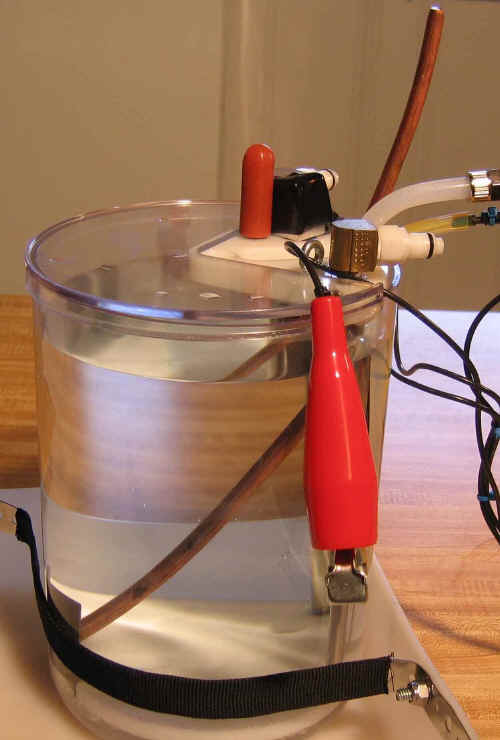

Coiler Curved or Straight Rod:

This system introduces a new feature that improves test repeatability dramatically. This is the ability to measure coiler curved rod as shown in the cell to the immediate right. Testing coiler curved rod rather than straight rod eliminates the rod straightening processes, which introduces artifacts into the surface. Furthermore over 20% more of the rod surface is tested for the same electrolyte level height. This cell is designed to accepts the traditional straightened rods as well, as shown in the far right image. |

|

|

![]()

Environmental:

Dustproof enclosure

Operating Temperature: -20oC to 70oC

Storage Temperature: -40oC to 70oC

All circuit boards are internally mounted on vibration isolators

Electrical:

Universal Input Voltage 90-264 VAC, 130-370 VDC, 47-63 Hz

Requires a maximum of 120 Watts

Input Surge current, over voltage and over load protection

Current output to the electrochemical cell can range from 0.1 to 30 mAmps with a maximum voltage of 2.5 Volts. (Very low current DC voltages do not exceed 12 Volts.)

12 VDC output to the EMM at a maximum of 4 Amps.

Three externally replaceable fuses

A system power toggle switch

DB-9 female connector for RS-232 communication (EIA/TIA-574)

Ethernet connector

Rugged connectors for the cell and EMM leads

Control Firmware:

The controller comes pre-installed with all the necessary firmware to perform all testing right out of the box.

LCD Touch Screen:

Waterproof and dustproof

Colors: 256/65,536

Horizontal Viewing Angle (degrees): 120 (typ.)

Vertical Viewing Angle (degrees): 50 (Top) 40 (Bottom) (typ.)

Screen Resolution: 320 x 240 (QVGA)

High Brightness LED Display (cd/m2): 560 (typ.)

Contrast Ratio: 600:1 (typ.)

Enclosure:

16-gauge steel, powder coated

Overall Dimensions: Height: 16" (406 mm), Width 15" (483 mm) & Depth: 10" (254 mm)

Mounting Hole Dimensions (four holes): 10-1/2" Horizontal by 14-1/2" Vertical (267 x 368) in (mm)

Key-Access Lock

Industry Standards:

NEMA/EEMAC Type 4, 12, and 13

UL 508A, File No. E61997: Type 4 and 12

CSA, File No. 42186: Type 4 and 12

VDE IP66

IEC 60529, IP66

Wall-mounting brackets required to maintain UL/CSA external mounting

requirement.

![]()

All firmware is embedded into the controller. Just turn the system on and its ready to start testing within 5 seconds.

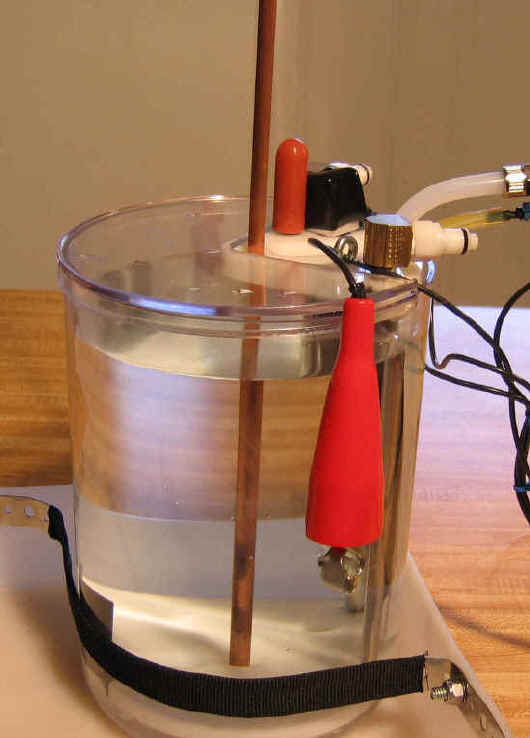

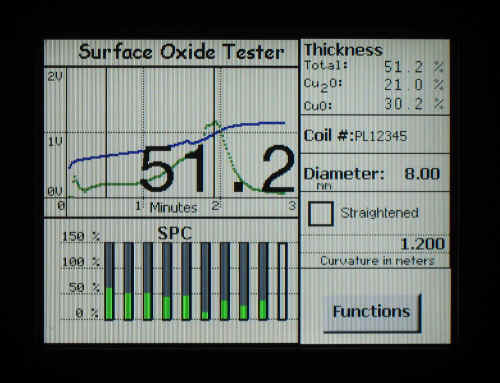

An example of the main screen shown on the LCD touch screen after a test is shown below.

One very useful feature provided in the software is that the results can be displayed as percentages of a key grading limit instead of in Angstroms. This gives the most meaning to the results. For example, the screen below shows the results of the same test as in the screen above. However, with the screen below the user has entered in a grading limit of 400 Angstroms and thus it shows that the results of this are about 50% of the grading limit.

The functions button at the bottom-right of the screen leads to fifteen password-protected administration screens each containing user-friendly and valuable features. These include:

|

current density control, | |

|

current control, | |

|

electrolyte maintenance control, | |

|

RS-232 communication (EIA/TIA-574) data collection and diagnostics, | |

|

LCD touch screen settings, | |

|

electrical calibration and | |

|

physical calibration. |

Overall Dimensions within sample tray: Height: 11-1/2" (292 mm), Width 18" (457 mm) & Depth: 12-3/4" (324 mm)

Dimensions outside of sample tray (cell alone): Height: 11-1/2" (292 mm), Width 9" (229 mm) & Depth: 7" (178 mm)

Adjustable electrolyte volume: 1/2 gallon to a gallon (1.9 to 3.8 Liters)

Level Sensing

Zero-maintenance auxiliary and reference electrodes

Supply pressure of nitrogen or argon to the Deareation Tube: 0.5 - 1 psi (3.5 - 7.0 k Pa)

Three quick disconnect couplings for mating with the EMM

The EMM automatically maintains the electrolyte by rapid electrolyte refreshing and consistent deaeration.

Overall Dimensions: Height: 6" (152 mm), Width 12" (305 mm) & Depth: 12" (305 mm)

The EMM rapidly connects to the cell and reservoir via Color coded tubing and quick disconnect couplings.

5 galloon (19 Liter) reservoir with:

Quick disconnect coupling in its cap for mating with the EMM and

Air vent

![]()

|

A digital manual in .pdf format (84 pages & 58 color photos) | |

|

The Upload Manager software can be installed on a computers (running windows) and used to upload the latest firm-ware versions to the controller via the RS-232. (Note: The system will work right out of the box, with no need to install the Upload Manager at any time, but when improvements are made the system can be updated.) | |

|

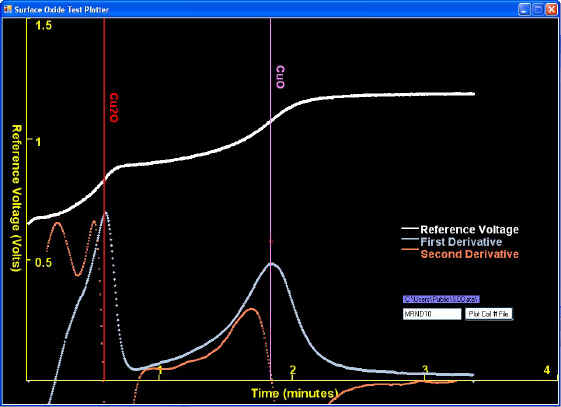

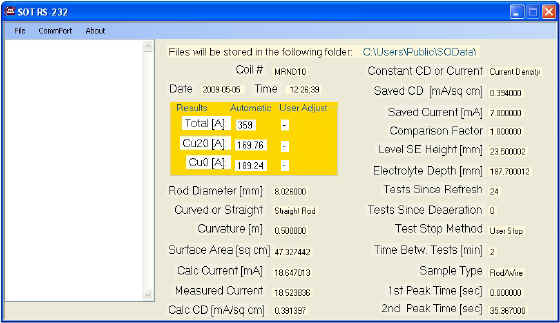

While our tester does not require interaction with an outside computer, we provide an advanced Test Capture Software for users who desire to display, store and perform more detailed analysis on their computers. (Typical Windows from this software are shown below.) (This software is not supported for every computer.) |

| This CD also contains example (open source) software that shows the user how to interface with our system via the Ethernet. |

![]()

Copper Foil:2 mil (51 �m) thick, 2" (51 mm) wide and 50-foot (15 m) roll of copper foil for physical calibration and test comparisons. (Note: Use of the foil is not needed for run tests, but it is recommended to properly understand the results.)

|

|

|

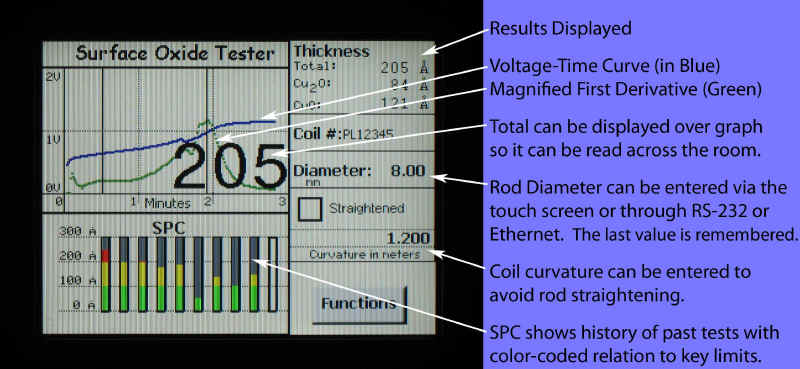

The photograph to the right illustrates one valuable feature designed into the system, namely, that the cell is very easily cleaned. The cell readily disconnects electrically and can also disconnect from the EMM through quick disconnect tube couplings. All cell components can be swiftly lifted out of the vessel. |

![]()