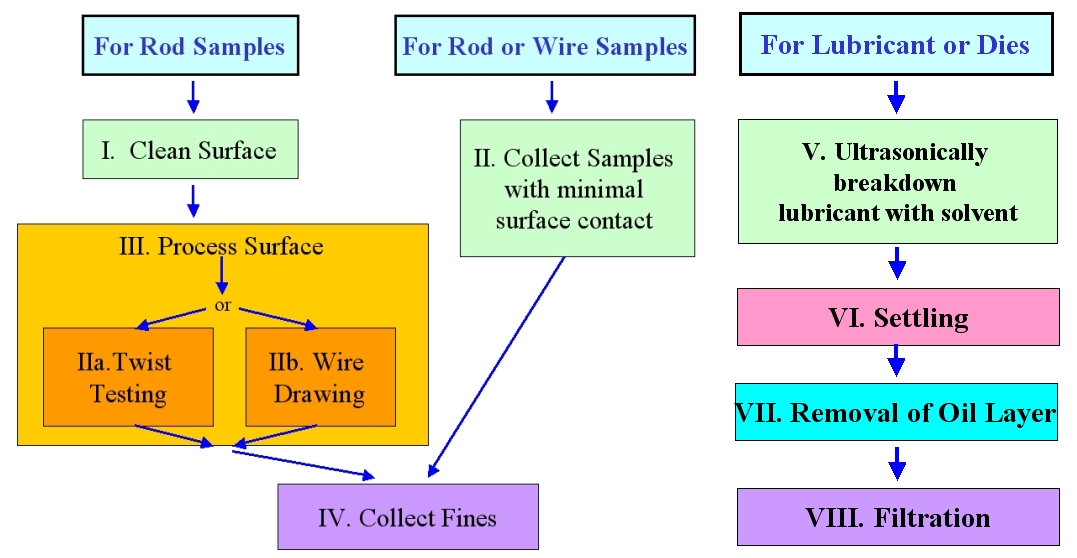

The Fines Potential Test is mainly used to predict the relative quantity of fines that will be generated when various rod sources are drawn. It can also be used to analyze wire drawing operations for their degree of fines generated.

|

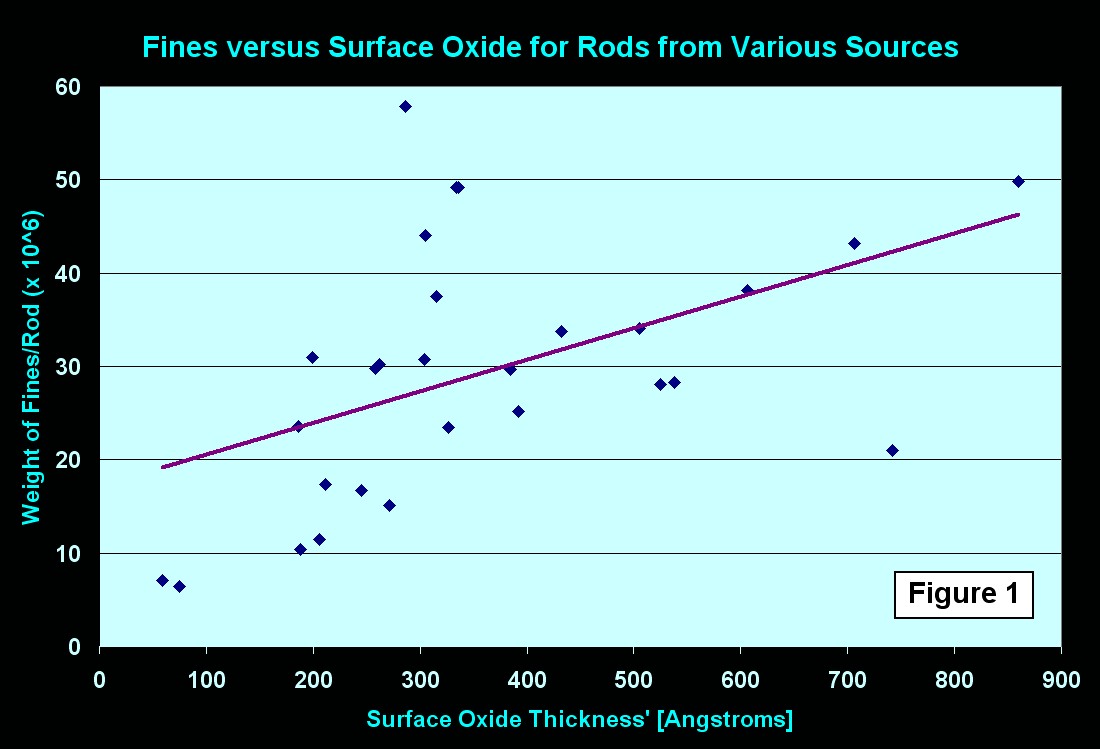

This instrument has been used for over a decade but it was just introduced to the Wire Industry in a 2008 paper by Pops and Baker, which won a �Best Paper Award� [1]. The FPA can collect fines generated by two phenomena: Rod Potential Fines: The rod making process introduces damage to the rod surface, which will readily generate fines during drawing. Thus, monitoring the Fines Potential of rods will predict the volume of fines those rods will readily produce, even under optimal drawing practices. Figure 1 shows a very dramatic illustration of this technique, where Rod Potential Fines were shown to highly correlate with surface oxide test results [1 & 2], which makes sense once the concepts involved are understood. Figure 1 is more dramatic considering it encompasses data taken from a variety of a rod sources with different surface processing, including: acid pickled, alcohol cleaned and shaved.

|

|

|

Wire (or Rod) Fines

Held on the Surface:

Most fines produced during wire drawing using liquid lubricants

remain on the surface of the wire.

Thus collecting these fines from the wire surface can provide

valuable analysis of the fines produced at each die in a wiredrawing

machine. It can also

immediately quantify the changes to the drawing process.

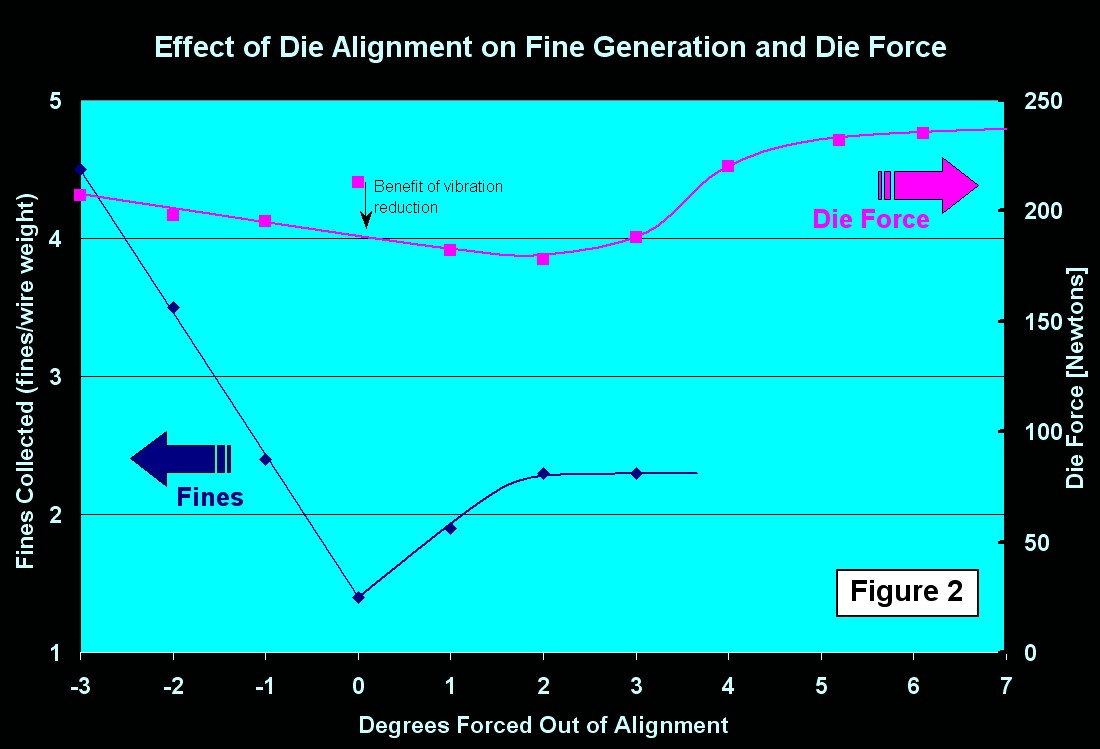

Figure 2 shows an example of the later where a roll was used to

guide the wire into the die & the optimal position of that roll was

rapidly determined via use of the FPA [3].

After collecting one of both types of fines, they can be weighed and normalized or they can also be examined microscopically (see Figure 3 for example) and metallurgically (see Figure 4 for example and Refs. # 1 & 4 for more information). |

|

Cost Savings Revealed: The

ultimate advantage of using the FPA is that it can lead to fines

reduction either:

Reducing

fines extends the life of the lubricant and reduces filtration waste,

both resulting in immediate cost savings due to lower disposal costs.

Furthermore, diminishing fines helps prevent wire breaks and

magnet wire enamel faults, which also result in cost savings.

With Rod Fines Potential analysis, reduction in wire breaks can

readily be achieved by directing high fines potential rod coils away

from less forgiving drawing processes. |

|

References:

�Formulation,

Analysis, and Measurement of Fines,� H. Pops and G. Baker, Wire Expo

2008 Conference Proceedings, June 2008.

�New

Developments in Rod Surface Measurement and Analysis,� G. Baker and H.

Pops, Wire Expo 2008 Conference Proceedings, Wire Journal Intl., June

2008.

�Some

New Concepts in Drawing Analysis of Copper Wire,� G. Baker and H. Pops,

Metallurgy, Processing & Application of Metal Wires, TMS, Warrendale,

PA, 1996, pp. 29-42.

�Correlation

of Surface Quality, Subsurface Quality and Fine Generation Analysis,� G.

Baker and R. Wright, Wire Journal Intl., Vol. 29, No. 10, Oct. 1996, pp.

76-85.

For more information about this system click here.

For information on Surface Oxide Testers: Click Here.

Coming soon: A preview of our next paper entitled, "Practical Methods of Reducing Fines Generation."

![]()

"Fines Generation" may also be referred to as: Fine generation, metal working debris, wire drawing debris, metal particles, filtration of fines, fines filtration, metal working wear or metal working tribology. This test is also referred to as ultrasonic fines removal. Fines are also referred to as dusting.

![]()